After years of scrounging for good electrical parts for my '66, I finally found an original '006 coil.

The primary resistance is 2.1 ohms. The secondary is 9.7K ohms.

I measured the turns ratio using 100Hz sine wave at 86:1. With a 200V primary voltage this coil is good for 18Kv. I have not measured the primary voltage, however. (That's very dangerous!)

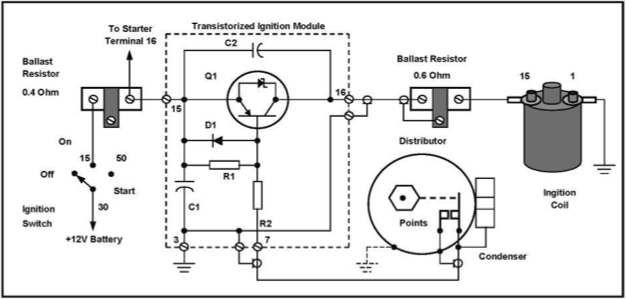

Of course, on the primary side these were used with a ballast resistor for normal operation. Even though I measured 1.3 ohms in one test, the nominal value is 0.9 ohms I am pretty sure. So that gets you three ohms during normal operation. The coil charges through this resistor so it's an RL circuit, not simply possible to do a simple calc without knowing the coil inductance.

In the days before electronic ignition, more than about four or five amps would burn up the points in no time, even with the capacitor present. So the points were the rate-limiting factor on how low the coil resistance could be (and how fast you could charge the coil).

With modern solid-state ignition modules, lower-resistance coils could be used and much higher current used to charge them.

I always wondered about the evolution of the ignition system-- from Kettering to 3 pin CDI (points triggered) to 6 pin CDI (reluctor triggered) then back to a low resistance coil that was triggered directly by the DME. Then in the 964 and 993, external Bosch ignition modules were used. If you look at what Porsche/Bosch were doing with the water cooled cars of the period, that's also a useful guide (however, the 928 used two coils).

Anyway, Porsche didn't have an issue using a single coil all the way through redline once there were modern igniters to switch it. I think that's pretty interesting, that they discarded capacitive discharge ignition in favor of inductive.

Contrast this SWB coil resistance with the later CDI coil, which is basically a step-up transformer (Bosch Nr. 0 221 121 001). The CDI coil doesn't store ignition energy between pulses-- the ignition energy is stored in the capacitor, and that gets dumped into the coil when the CDI fires. The CDI coil primary resistance is between .4 and .6 and 650 to 790 ohms on the secondary side, according to Bosch. It's a smaller coil than the ones used before, or after, because it's being hit with a 460V pulse from the CDI, hence the turns ratio is probably lower than an inductive coil, with a lower secondary resistance as a result. This CDI coil was used unchanged from 1969 on the 911E through 1983 on the SC.

In 1984 with the advent of Motronic, the coil changed to part No. 944 602 115 00, Bosch No. 0 221 118 322. That coil had a primary resistance of between 0.4 and 0.7 ohms and a secondary resistance between 5.0K and 8.7K ohms. That same number was also used on the 924S, 944 (all versions including 968), the 964 and the 928 from 85 to 88. The inductance of this coil is claimed to be 3.6mH.

The 993 Coil (a dual pack that mounted on the engine mount crossbar) has a primary resistance of 0.58 ohms and a secondary resistance of 6.92 ohms (thanks Bazar1 from Leesburg, GA!)

See how the primary resistance dropped after the advent of electronic ignition?

Stay tuned. . .

Reply With Quote

Reply With Quote