.techniques and lessons learned.

I decided to try to recover my 380mm four spoke steering wheel from my '69 911T. I love a challenge. It's probably worth the money to pay someone to do it, but if you have time on your hands and get a satisfaction of doing something yourself you should try a DIY steering wheel recover.

First of all, you do not need to buy a kit. You can get all the necessary materials and tools yourself. The following is how I did it. You might have your own techniques and methods. Please post them here for others to use.

I bought the black leather on Itsy.com. I bought half a hide for only $35. It was slightly thicker than the original steering wheel leather. I used a heavy waxed thread that I bought on mainethread.com. I also used a thinner upholstery Dacron thread to stitch the ends together. You will need the following tools:

Straight edge / carpenters square

Circle template

Single edged razor blades

X-Acto Knife

Skiving tool bought on Ebay, used to taper the ends of the leather, so when you fold the leather over, it's not too thick

Scissors

Fabric marking pencil

Curved needles

Leather hole punch

Hook tool for hooking the thread as you lace and pulling it tight.

Masking/painters tape don't use a tape that will pull the finish off the leather

Digital calipers very helpful

Contact cement

Before you remove the cover note the stitching patterns. Mine had a XXXXX pattern around the rim and a baseball >>>>> stitch on the spokes. Note the leather extends onto the metal spokes. Carefully remove the steering wheel cover. Note inside of the seam and the end of the spokes. That is where the skiving tool is use to taper the leather before it is folded over and glued. The old leather is practically useless as a pattern for making a new cover. Note that the leather tapers slightly as the ends of the spokes. I made a paper pattern only to find the spacing of the spokes.

Next, I cut leather pieces to test the width that I needed to cut the cover and to practice stitching. All leather will be different thicknesses and will have different stretch properties, so you will have to determine how wide to cut your cover. My first test piece was 65mm wide and about 100mm long. I found that it took a lot of pull to close the gap on the seam, so I went with 66mm. That extra 1mm made all the difference on how the leather came together properly. I also cut a long test piece (long enough to go along a spoke on the front side around to the backside. I practiced my baseball stitch and found that 35mm was a good width for the spokes. I'll discuss how to do the stitching a little later so reference that section to practice your stitching.

I next cut the leather cover. I used the fabric pencil to lightly mark my cuts. I referenced my paper pattern to mark where the spokes align. When you cut the cover, cut the spokes EXTRA wide. Why? Because you are going to make the cover about 1 to 1.25cm smaller in diameter than the steering wheel so it will stretch tight when you mount it. Your spoke measurements will shift. Also the spokes are not exactly perpendicular to the wheel rim. I cut the spokes to width after I sewed the ends together. Remember to leave some extra leather on the ends where you will sew the ends together. I used a carpenters square to make the lengthwise cuts. Cut one side, then carefully measure (I used my digital caliper) and align your straight edge so it is EXACTLY parallel to your first cut and exactly 66mm wide (or whatever width that works for your leather). After the cover has been cut out, use the skiving tool and taper each end. Next, sew the ends together. Smooth side to the inside. I used a leather punch and punched holes across the width and hand sewed this seam using the thinner Dacron upholstery thread. If you have a heavy duty sewing machine use it to sew this seam. Next take a block of wood and use the edge to run it along the back side of the seam. Doing this will help fold over the ends. Use contact cement and glue down the tapered ends. You should have a nice tight and fairly flat seam.

Now we will trim the leather spokes to width. Leave the leather spoke lengths LONG at the point. Put masking tape on the backside of each of the four leather spokes. Put the cover on the steering wheel starting with your seam exactly at the bottom of the wheel. You will see the old imprint of the seam. It should be a fairly tight fit. Make sure the leather is evenly stretched on the wheel and centered side to side. Now make a few tick marks on the masking tape along the center of each leather spoke, front and back. Now take the cover off, turn it back side out. The masking tape will be to the outside and you should have the exact centers marked. Use a straight edge and connect your tick marks. You will notice that the spokes are not exactly perpendicular to the outside wheel and your marks will show this. Using the center lines, I marked my widths. (I used 35mm, your measurements might be different.) Next I trimmed the spokes to width. Again, do not cut the length. Leave them long. Note that the corners of each spoke is a radius, not a right angle. I used my Xacto knife and a circle template to cut the radius. Pull off all the masking tape.

Next, turn your cover right side out. You will now pre-punch all of the holes except along the spokes. I had a straight edge with metric markings. I went with a 5mm spacing. That spacing is slightly smaller than original, but is easier to measure. I had a long board about a foot wide and laid it on the kitchen table, sticking out towards me. Lay your cover around this board and start punching holes, starting either side of the bottom seam. First do one edge, then the opposite edge. Make sure the holes line up with each other exactly from side to side. i.e. don't have 30 holes on one side and 31 on the other. Haha. I used a square to make sure the holes lined up. So now all four sections should be punched. (top, bottom, and between spokes, but not along the spokes.)

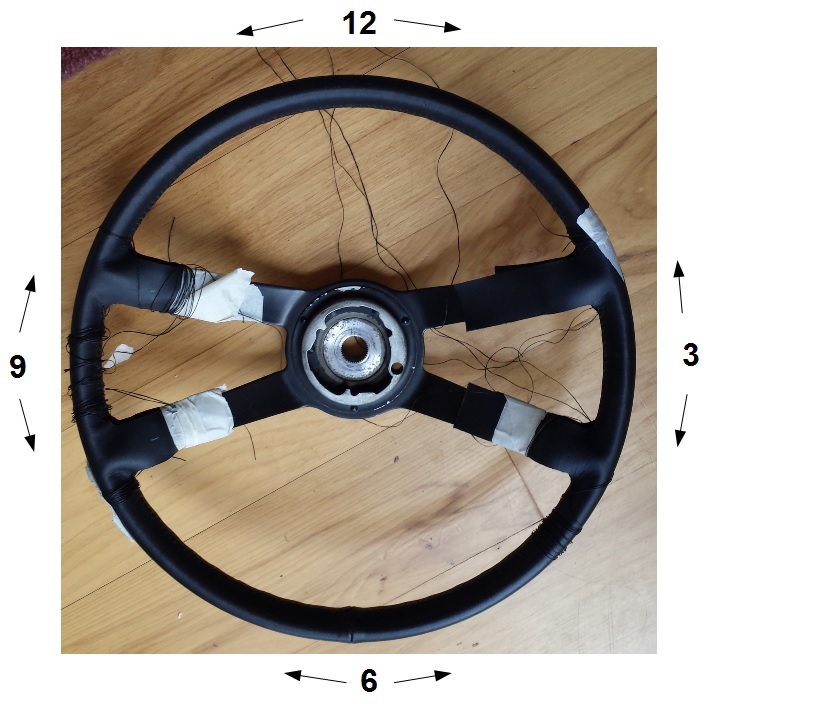

Now comes the fun part the stitching. Put some contact cement on the inside of your seam and on the bottom of your steering wheel. Line up the cover seam with the bottom of your steering wheel, centered side to side and put the cover back on the wheel. Again make sure the cover is evenly stretched and the leather cover spokes EXACTLY line up with the steering wheel spokes. You can put some contact cement along the wheel and cover. 10 and 2 o'clock and 4 and 8 o'clock positions. Don't over do it. Use masking tape at these points and at the spokes to hold the cover in position. You will use FOUR start points for the stitching: the 12, 3, 6, and 9 o'clock positions. At each position you will stitch counterclockwise and clockwise, so you will have EIGHT threads running around the steering wheel terminating along the spokes. WHAT?? Trust me on this.

Reply With Quote

Reply With Quote