Hi everyone,

I warn you this might be a long post. I am in the process of restoring a 1970 "S" and after assembly of the transmission I am now fitting it to the engine.

I have studied the WM, a lot of different posts both here and on the bird's forums. Many don't seem to come with a final conclusion to them. I hope my tests and observations might be helpful and not too redundant. I treat this post as a gathering of the experience I acquire on this system.

So I'm working on an October 1969 produced 1970 Model year "S", Transmission case was replaced by an "early" series of 1970 mag cast as the original-match has some pretty nasty cracks on it. They are both from the same series i.e. the type and serial number are stamped on the botton rib and not like the "updated" on the square space under the differential area.

-Flywheel is original but has been machined (probably more than once as it is quite close to the minimum thickness prescribed in tolerances; wear limit of 8,5mm).

-Pressure plate is a steel Sachs replacement that was already on the car before the restoration process, Cast number is: 3032 055 099, etched number is: 3082 018 431. According to Google searches, it seems to be an appropriate replacement for a 1970 225mm clutch.

-Disc is a brand new Sachs, replacement equivalent of 911.116.011.07, number: 1878 005 614. I didn't record thickness but I recall having measured it and it was a bit thicker than the spec'd 8.1 +/- 0.4mm. Pretty sure it was more like 9mm.

-Throw-out Bearing is a Sachs 31 3151 003 501. *****This one does move on the pressure-plate diaphragm fingers where it is held, I don't have any others to compare to, from other manufacturers experience I know it could be normal...*****

-Clutch Pivot bolt I have a aftermarket brand new one made by "JimmyT". Very pretty little part.

-Washer New OEM Porsche, 911.116.743.01. It is tapered, has a total thickness of 6,0mm

-Flat spring or some might call it the leaf spring, new OEM Porsche 911.116.774.01. Thickness is 1mm

-Throw-out fork original fork that was on the car, again don't have another to compare with, but seems to be in good condition. No bent sign, the ball cup seems to move well on the pivot bolt (prior bolt had some significant wear on but didn't break). A bit of wear where it contacts the leaf spring, nubs are still looking good.

First assembly

So after many readings, I went along the "flywheel has been machined, add a shim under the pivot bolt to compensate"

I fabricated a flat washer out of 0,7mm sheet metal (blind shot at the thickness as I am missing a lot on information about key measurements for this compensation).

Made the O.D. the same size as the Porsche tapered washer.

Install order: Transmission case, leaf-spring, 0,7mm shim, tapered washer (taper facing the fork), Shift fork (ball cup greased with MoS2 anti-friction mixed with some Extreme Pressure grease from Porsche), then the pivot bolt.

We could say that the pivot bolt base here is sitting 7,7mm from the transmission housing

Mated transmission and engine together, VERY easily fit the fork on the T.O.B then begin to proceed with some tests, measurements.

First I noticed the fork is totally unsupported. It doesn't have any preload from the leaf spring to keep the nubs pushed on the T.O.B, hence the reason it was so easy putting it on.

Pushing on the fork, so it just touches the tabs of the T.O.B, I measured the distance from the front-facing side of the fork to the front-facing side of where the actuator cable-end is held on the transmission housing. Result: 67-68mm

The leaf spring is pretty far from the fork, I measured a good 5mm between the tip of the spring and the fork.

Then managed to fit an homemade cable trunnion on the fork (what was previoulsy installed on the car upon disassembly), put a long bolt through the eye on the differential cover, 2 nuts on the bolt and used it to actuate the clutch lever.

Distance (still measured at the fork to main case): 54mm

When fully actuated like this, the fork touches the pressure plate and the engine cannot be turned with a wrench, the fork jams into one of the recess on the casting of the P.P.

That give a total travel of about 13-14mm; which is less than what I've found online of an ideal ~15mm.

Transmission in gear, I am able to turn the output flanges of the differential by hand and can hear a light sound from the clutch disc. I still don't like that as I feel there is not enough travel, fork is loose when nothing is pushing on it, and when fully acutated it jams the engine rotation.

I just can imagine the noise this would create, let alone the wear that will result from this rubbing.

Analysis and thinking...

Little head scratch and transmission comes off. At that moment I started to measure and document all parts I really had on hand, which I've listed previously. Did some search to make sure 100% I had all the right parts for a 2,2L and a 911/01...

Started to fumble around thinking about that *famous* additional shim... Thought about trying to install it between the transmission housing and the leaf spring, at least that would bring the spring/fork closer to each other, but less than 1mm, I need more than that. Read about some that were saying "Try bending the tab a little". Thought I would give it a chance, put it in the vise, hammer it to accentuate the bend, went too hard on it and I cracked it. Result I need another one...

Brought the old one at least to pursue my tests... Here I noticed the previous install that was on the original transmission, it was assembled with a normal M8 flat washer, the leaf spring, then a split-lock washer, then fork and pivot bolt. I measured the "angle" of the leaf spring: "washer" part laying flat on the table and at what height the end of the tab would be from the table surface. That gave me about 9mm. Decided to try bending it but in a different manner, I opened my vise so I could put the bent part of the leaf spring in between the jaws, then with the ball point of the hammer, softly worked it. Not too hard, and not too much this time. Measured another time, I got it to move about 2mm as I now measured 11mm.

Second assembly

Still thinking about the fact I don't have enough room for the fork to move. I decided to put away my shim and the new OEM tapered washer.

I took 2 split lock 8mm washers, measured them and they come at 4mm thick total. Decided to try these as the O.D is fairly small vs a regular flat, or a spring washer (the wavy ones).

I thought it would leave more room for the fork movement as the purpose of the taper on the Porsche part.

Reassembled in the order, transmission housing, leaf spring, 2 spring washers, fork and the pivot bolt. Present pivot bolt base is sitting at 5mm from transmission housing. Transmission installed on the engine.

First thing noticed, I have to work against the leaf spring in order to move the fork so I can turn the T.O.B.

I get about 1mm preload from the leaf spring on the fork once everything is in place, which makes sense for the purpose of the part. It also takes up the small slack of the T.O.B-to-P.P.

Fork distance in relaxed state: 75mm

Clutch actuated: 59mm, there is still a few mm between the fork and the pressure plate.

Total travel: 16mm, figure this could go to about 18-19mm before the fork hits pressure plate again.

Then I started to think about the statements where some say angle won't be right as the pivot should be closer to the clutch...

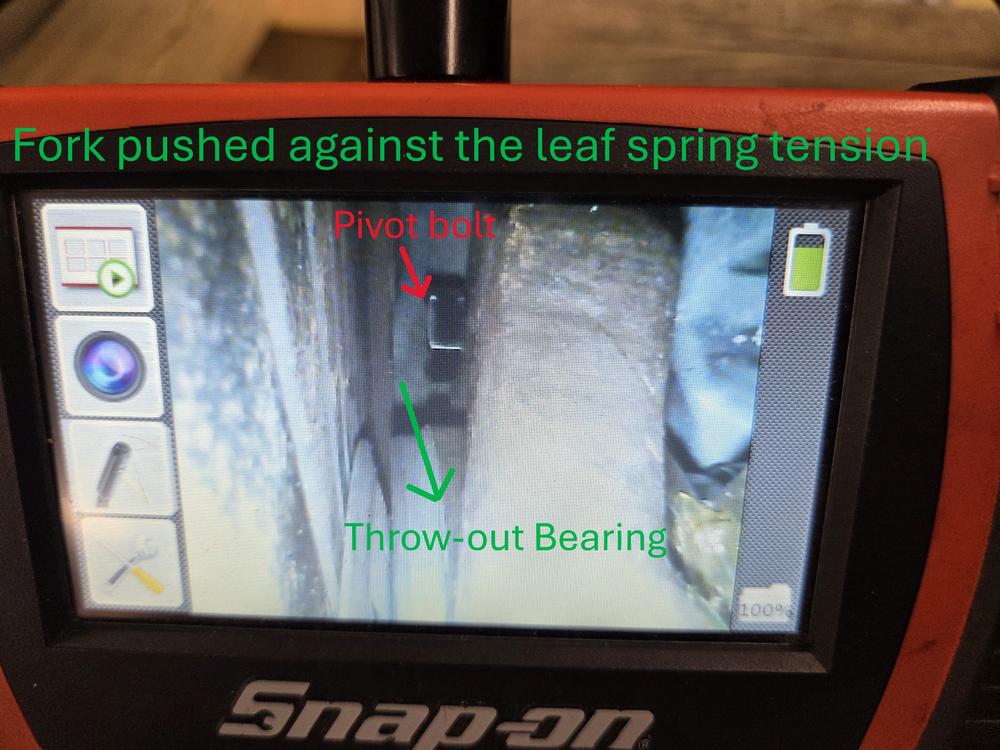

Brought my camera, tried my best to shove it through the inspection holes at the top and look at the pivot bolt head side and see the fork in relation to it.

I haven't done it on my first assembly (all OEM + shim) but by judging what I see here, along with the fork positionning, it seems it would put more strain on the pivot bolt as the fork would already be at an angle in relaxed position. Whereas with the experimental setup the fork if pretty flat, or on the same plane as the pressure plate.

Another point I didn't mention but I feel is worth noting, the M10 nuts used for the bellhousing stud are DIN70615, which makes them having a smaller a/f than a regular 10mm nut.

A regular nut would be an a/f of ~17mm whereas the DIN 70165 is either 14 or 15mm. (New Porsche ones p/n 900.157.002.03 are 15mm)

It does make a difference, especially if the fork is really close to the pressure plate, the bigger (17mm a/f nuts) are at chance to touch the fork also, the smaller ones give a bit more room.

Ask me how I found out...

Anyone wanna chime in or add information about this?

Here are some photos.

Set-up to push the clutch fork, simulating pressing the pedal

All OEM parts, relax state holding the fork pushed against the bearing as it is very loose.

Gap in relaxed state, all OEM parts, total thickness under pivot of 7,7mm

All OEM parts, clutch “fully” actuated, fork hitting pressure plate.

Relaxed state of second assembly; total thickness under pivot of 5mm

Fork to pivot bolt relation, actuated state

Fork to pivot bolt relation, relaxed state

Fork to pivot bolt relation, fork pushed against the leaf spring tension

Reply With Quote

Reply With Quote