Is there a replacement delrin piece available from somewhere? I see that a company makes delrin cap but I believe that is for the earlier racks.

Thanks in advance

Will

Is there a replacement delrin piece available from somewhere? I see that a company makes delrin cap but I believe that is for the earlier racks.

Thanks in advance

Will

Once you let the smoke out, It's hard to put it back in

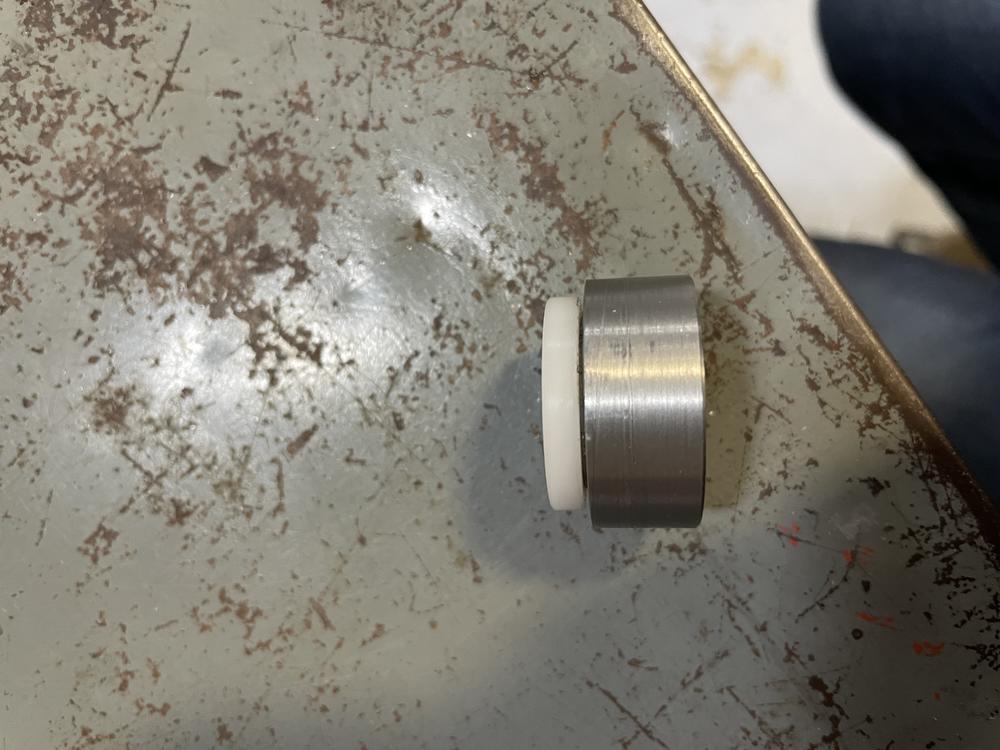

Got one for my 1969 steering rack from Sierra Madre $21.43 in July 2020.(part # SMC.347.929.00 The plastic puck had a reverse taper that snaps into the matching taper on the steel part. You have to squeeze it pretty good. Used a vice.

My steel part did not have the 4 holes inside, so maybe there are different pucks for different years?

yes I saw that part. I believe that puck is for the earlier racks.

Once you let the smoke out, It's hard to put it back in

I just did replaced mine on a 68 rack.

https://www.stoddard.com/sic34792900...92900-sic.html

What year do you need?

Needed one for a 71. The earlier puck is a smaller diameter so it cannot be put into later racks.

I ended up machining a new piece that takes the newer replacement delrin but had the correct diameter to fit inside of the later rack.

Once you let the smoke out, It's hard to put it back in

I tightened mine until 3 threads were left showing. That is how it was when I removed it. Mike's Restorations on Youtube had the same.

Found this thread as a result of rebuilding my rack and finding the same issue with my 71. Was wondering how you attached the delrin disk that you machined to the steel puck?

The other option that I was considering was to 3d print the part in nylon, anybody tried this before?

I machined the puck and used the replacement delrin bushing that be purchased at https://www.stoddard.com/sic34792900...92900-sic.html

The older style had a lip that the delrin bushing would fit on to to prevent it slipping out of place. I oversized the circumference of the lip ever so slightly so it would retain the bushing on the part I machined.

If the car was still around and it wasn't put together I'd get some more pictures to help my explanation

You could probably 3D print the entire bushing from delrin... just dont breathe in the fumes

Last edited by wkershaw993; 08-31-2022 at 06:39 AM.

Once you let the smoke out, It's hard to put it back in

Thanks for the extra information, I get it now you actually machined the metal puck to match the aftermarket delrin cap. In the end I decided to have a go at designing and printing one. I’ve used ABS filament first to see how it went and was quite happy about the fit and the strength. Will need to source some delrin next. Looks as it can be quite difficult to print without a temperature controlled cabinet. I suppose time will tell if it’s entirely suitable.

He’s a photo of the ABS printed parts.

Looks like it turned out well. I wonder what other people with the later style racks are doing for their wear pucks. Maybe it is one of those things that people dont check.

You could start with a solid piece of Delrin and machine it down to match the original dimensions. I have a feeling making a mold of it for injection molding would be cost prohibitive given the limited demand for these.

Once you let the smoke out, It's hard to put it back in